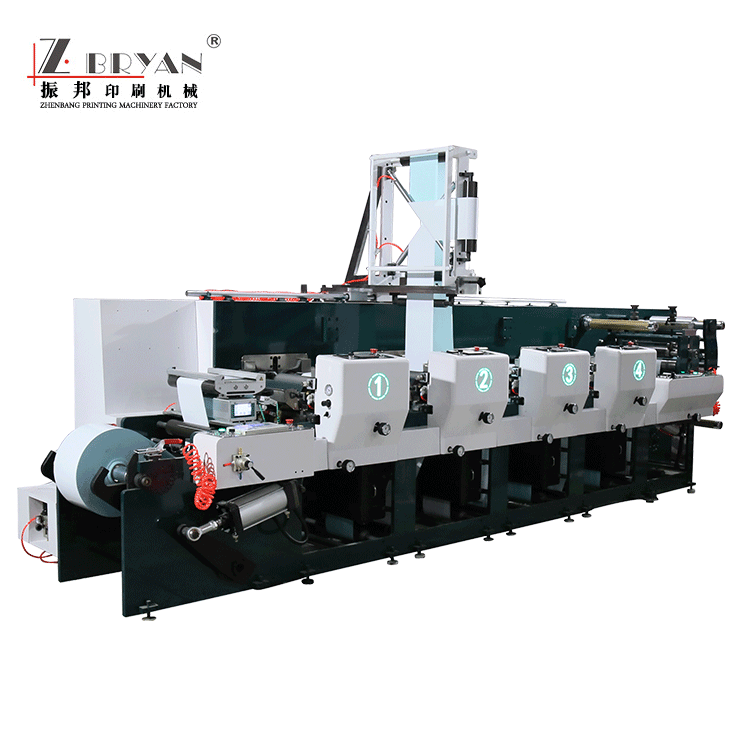

本机器特色

1.采用陶瓷网纹辊传墨。

2.各印刷单元采用360周向对版调节

3.随机配有三组模切工位,第一、第二组模切工位的模切辊和模切低辊可上、下互换,可作正面或反面模切并配有一组废料回卷单元,第三组模切工位可断张。

4.电脑纠偏装置设在印刷组前面,这样的设计令卷纸在整个生产过程中,都保持在正确的左右位置上。(标配)

5.可按用户需求选配切断张的输送台装置,由第三组模切工位断张后,使产品整齐输送出来。

6、放卷、收卷由磁粉自动涨力控制,并可加装双收卷

7.可按照用户需求选装静止画面监控系统,在高速印刷时监控图面质量。

8.停车时墨辊可自动脱离,并低速运转,以防水墨干结,

9.主电机采用进口变频无级调速。

10.从筒料供纸、印刷、上光、自动关红外烘干、覆膜、收卷或切张一次完成,是各类印刷厂印刷商业票据、高档不干胶最理想的机型,

11.全自动电脑套色,独立双收放料架(双气胀轴)。

12.自动退版装置,断张+输送平台+理纸装置,静止画面。

Product Overview

This machine characteristics

1.Using ceramic roller to transfer the ink.

2.Each printing unit adopt 360 for registration.

3. Equipped with three die cutting stations, the first and second die cuttingstation of the die cutting roller and die cutting low roller can beinterchanged, can be used for front or back die cutting and is equippedwith waste rewinding unit, the third station is sheeting.

4. The computer web guiding is located in front of the printing group, sothat the roll paper is kept in the correct left and right position throughoutthe production process.(standard).

5. Can be selected according to user needs to install the conveyor tabledevice, can be transported neatly by the conveyor table device.

6, the unwinding, rewinding is controlled by magnetic powder and can beinstalled double rewinding.

7. video monitor is optional for the customers to monitor the quality of thepicture during high-speed printing.

8. When stopping, the ink roller can be automatically disengaged and runat low speed to prevent dryink.

9.The main motor adoptsimported frequency stepless speed adjust.

10.Unwinding, printing, varnishing, lR drying, laminating and rewindingcan be finished in one process, this kind of printing machine is best for eachprinting companies to print on adhesive-paper labels and othercommerciallabel.

11.Automatic computer registration ,independent double retracting anddischarging rack(double airshafts).

12. Automatic return the printing roller device, sheeting ,conveyingplatform+ paperarrangement device,video monitor.

湖北ZB-350/450机组式标签印刷机

共有-条评论【我要评论】